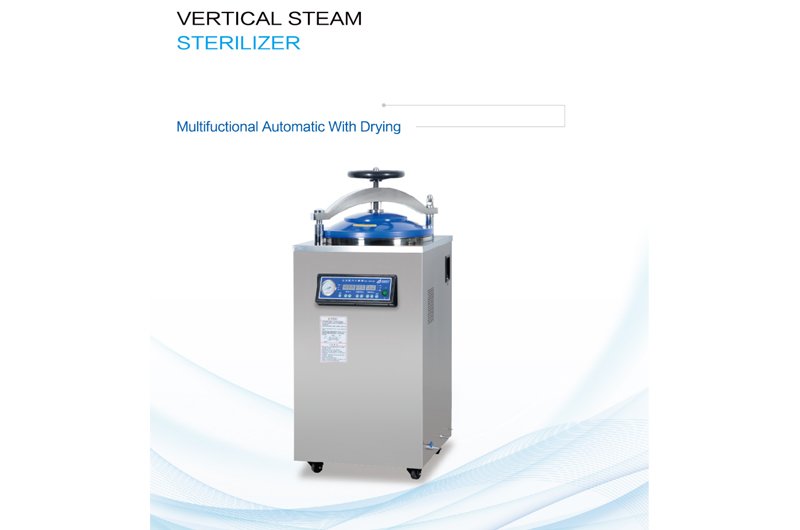

- Autokláv

Jak funguje autokláv? Komplexní přehled

- Podle kelingmedical

Co je to autokláv?

Tlaková komora zvaná autokláv sterilizuje zdravotnické vybavení a materiál pomocí páry za kontrolovaných podmínek. Z řeckých slov "auto" a "clave" vznikl termín autokláv, který odkazuje na samosvorný těsnicí systém. Zvýšením tlaku v komoře autoklávu vzniká horká pára, která je teplejší než vroucí voda. Vysoká teplota sterilizace v autoklávu zničí všechny typy nebezpečných mikroorganismů, takže ošetřené předměty lze bezpečně znovu použít.

—

1.1.1. **Mechanismus autoklávování**

Autokláv funguje díky mechanismu zvyšování tlaku. Zde je přehled hlavních součástí a způsobu fungování autoklávu:

1. **Tlak a výroba páry**

Topné zařízení uvnitř autoklávu ohřívá vodu a vytváří páru. Voda se po dosažení teploty varu změní v páru.

Vstřikování páry zvyšuje tlak v komoře. Pára dosahuje teplot vyšších než 100 °C, protože systém vyvíjí na vodu tlak. Pracuje při nastavených hodnotách 121 °C až 134 °C.

2. **Pronikání páry**

- Pára je velmi účinná při přenosu tepla. Pára vytlačuje veškerý vzduch z komory, takže každý povrch v prostoru je vystaven přímému teplu. Komora se naplní párou, která proniká do všech částí předmětů včetně tkanin a chirurgických nástrojů.

3. **Sterilizační proces**

Potřebná doba sterilizace nastane, když jsou předměty ošetřeny párou při požadované teplotě a tlaku. Během sterilizačního cyklu jsou mikroorganismy i **tepelně odolné bakteriální spory** zničeny intenzivním teplem.

4. **Větrání a chlazení**

Jakmile komora dosáhne bezpečné úrovně tlaku, pára odchází pomalým odvzdušňováním. Po sterilizaci projdou předměty regulovaným snížením teploty zpět na normální pokojovou teplotu. Cyklus sušení v některých autoklávech vysušuje materiály po sterilizaci.

—

1.1.2. **Klíčové faktory procesu autoklávování**

Účinnost autoklávování je do značné míry závislá na třech rozhodujících faktorech: **teplota, tlak a čas**. Naše nastavení přesně řídí cyklus autoklávování, aby byly zničeny všechny patogeny.

1. **Teplota**

Teplota v autoklávové komoře se pohybuje mezi 121 °C a 134 °C. Standardní sterilizační teplota je 121 °C, která se používá pro typické autoklávové cykly trvající 15 až 30 minut. Při použití teploty 134 °C trvá sterilizační proces pouhých 3 až 10 minut, během nichž jsou zničeny všechny bakterie v předmětech odolných vůči teplu.

Větší teplo zabíjí mikroorganismy rychleji, ale musíme řídit úroveň tlaku, abychom ochránili choulostivé materiály.

2. **Tlak**

Vyšší tlak napomáhá varu vody při vyšší teplotě, díky čemuž pára dosahuje účinnějších teplot. Pod 15 liber na čtvereční palec (psi) dosahuje voda teploty 121 stupňů Celsia, zatímco 30 psi umožňuje ohřát vodu až na 134 stupňů Celsia. Větší tlak způsobí, že pára pronikne hlouběji do materiálů a zničí všechny živé mikroorganismy.

3. **Čas**

Přesná doba potřebná pro působení páry ovlivňuje výsledky sterilizace. Délka sterilizace závisí na tom, kolik předmětů je třeba zpracovat a z jakých materiálů jsou vyrobeny. Doba potřebná ke sterilizaci závisí na typu nástroje. Chirurgické nástroje potřebují **15 minut**, zatímco ostatní hustší materiály je třeba vystavit delší době.

—

Co se děje s mikroorganismy v autoklávu?

Sterilizační proces funguje tak, že rozkládá buněčnou strukturu mikroorganismů, mezi které patří bakterie, viry, plísně a dokonce i bakteriální spory. Zde se dozvíte, jak autoklávování tyto patogeny eliminuje:

1. **Destrukce buněčných membrán**

Teplo z autoklávu rozkládá proteinové struktury uvnitř buněk mikroorganismů. Dochází k rozpadu buněčných membrán, což vede k usmrcení živého organismu.

2. **Narušení DNA a RNA**

Extrémní teplo poškozuje DNA a RNA mikroorganismů a brání jim v množení a přežití.

3. **Zabíjení výtrusů odolných vůči teplu**

Autoklávováním můžeme úspěšně zničit spory odolné vůči teplu. Tyto bakterie existují ve stavu odolném vůči teplu, který se nazývá spory, jež odolávají teplu i chemickým látkám. Tepelným a tlakovým ošetřením párou se v autoklávu odstraňují tepelně odolné spory v předmětech.

—

1. Jak se obsluhuje autokláv**?

Pro úspěšnou sterilizaci je nezbytné naučit se autokláv správně obsluhovat. Zde je základní návod, jak správně používat autokláv:

1. **Příprava nákladu**

Připravte si předměty, které chcete sterilizovat, tak, že je očistíte a správně uspořádáte. Uspořádejte všechny materiály tak, aby na nich nebyly patrné žádné stopy povrchového znečištění.

Vložte předměty do autoklávovacích nádob nebo je uzavřete do sterilizačních fólií či obalů. Položte předměty do zásobníku autoklávu s dostatečným odstupem, aby pára mohla snadno procházet.

2. **Nastavení parametrů sterilizace**

Zvolte správnou teplotu a dobu sterilizace podle materiálu náplně. Většina autoklávů je vybavena automatickými programy určenými pro různé typy materiálů, jako jsou chirurgické nástroje, laboratorní nádoby a kapalné vzorky.

3. **Začněte cyklus**

Proces sterilizace zahájíte uzamčením dvířek autoklávu. Zkontrolujte, zda je plomba na stroji neporušená, a spusťte cyklus podle zadané doby.

4. **Postterilizační manipulace**

Po skončení cyklu nechte autokláv vychladnout, než otevřete jeho dvířka. Se sterilizovanými předměty zacházejte opatrně, protože jsou velmi horké. Nevyjímejte předměty z autoklávu, dokud neskončí vestavěná fáze sušení.

—

1.1.2. **Časté otázky týkající se autoklávování**

1. **Jak horký je autokláv?**

Autoklávy během sterilizace zahřívají předměty na teplotu od 121 °C do 134 °C. Autokláv pracuje při různých teplotách podle toho, jaký sterilizační cyklus spustíte a jaký materiál zpracováváte.

2. **Jak funguje sterilizátor v autoklávu?**

Vstřikováním vysokotlaké páry autokláv ničí mikroorganismy v ošetřovaných materiálech. Vysoký tlak v autoklávu umožňuje, aby se voda vařila při teplotách vyšších, než je běžné, a vytváří tak páru, která ničí všechny mikroorganismy v komoře.

3. **Jaký je proces odstraňování mikroorganismů párou?**

Pára z autoklávu poškozuje buňky a bílkoviny mikroorganismů teplem, které zastavuje jejich genetický materiál a zabíjí je. Vysokotlaká pára dokáže proniknout i do tepelně odolných spor, čímž je zajištěna úplná sterilizace.

—

#### **Conclusion**

Nemocnice a laboratoře v různých průmyslových odvětvích se spoléhají na autoklávy, které chrání jejich vybavení před škodlivými mikroorganismy. Vysokotlaká pára v autoklávu účinně ničí všechny mikroorganismy na různých materiálech. Znalost fungování autoklávů při různých teplotách a vysokém tlaku po určitou dobu chrání lékařské nástroje i bezpečnost pacientů.

📧 E-mail: inquiry@shkeling.com

🌐 Webové stránky: www.shkeling.com.cn

Těšíme se na úspěšné partnerství s vámi!